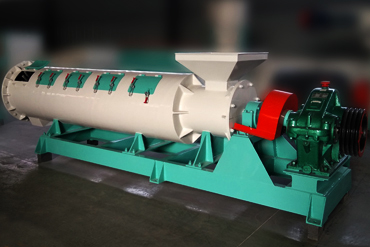

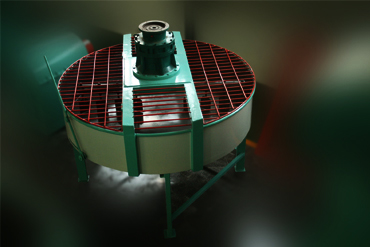

Wet Type Organic Fertilizer Making Machine

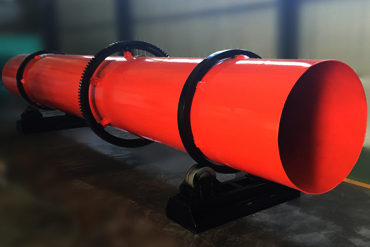

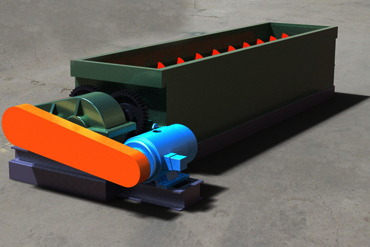

This organic fertilizer granulator is developed to keep continuous organic fertilizer granulation, achieving a super-efficient fertilizer granulation process in large-scale organic fertilizer production lines. It owns the highest granulation rate among all the organic fertilizer granulators, which convinces the manufacturers that this machine is right for them. It breaks through the conventional organic granulation process. Before granulation, the raw materials do not need to be dried and crushed. Direct granules can be processed into spherical particles and can save a lot of energy. The granulator can be customized according to your needs. This organic fertilizer granulator has a specialty for organic fermentation fertilizer granulation of livestock manure, pile retting fertilizer, green manure, cake fertilizer, peat, soil miscellaneous fertilizer, microbial, and other municipal solid waste. Organic fertilizer compressive strength is higher than disc fertilizer granulators and rotary drum fertilizer granulators.