What is Organic Fertilizer Mixing/Blending?

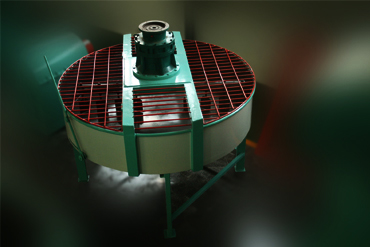

Mixing is the process of thoroughly combining different organic materials to produce homogeneous organic/bio-organic fertilizer granules. The mixture is generally a combination of dissimilar materials, e.g. Soya bean waste, barley and wheat straw, peat, lignite, sludge, municipal wet waste, vegetable waste, chicken manure, and cow dung blended in a specified ratio to produce Quality Organic Fertilizer Granules/Pellets. A Pan mixer is a vertical-type blending machine, being specially designed for large and medium-scale organic materials combining. Organic Fertilizer vertical pan mixer reduces blend time, improves blending uniformity, and decreases equipment cleaning time between batches. The whole blending process is done with excellent performance. Disc pan mixer is widely used in organic fertilizer production, especially large-scale ones. It has a larger capacity compared to a horizontal blender machine.

Here are the 3 more benefits of a disc pan mixer:

▽ Easy maintenance – Due to its simple structure, broken parts of the disc pan mixer can be easily replaced. It spends less energy compared to other organic fertilizer mixer machines and has the ability to make less noise, making pan mixer environmentally friendly machines.

▽ Low cost – disc pan mixing machines are designed to provide high blending performance while main components such as cycloidal reducer, blending discs, agitating shaft, and motor are protected. This increases the service life since spare parts are durable and do not need to be changed often.

Pan mixers also come in a variety of models with a variety of features/capacities to match the requirements of different applications.

Inner Structure of Vertical Pan Mixer Machine:

A vertical disc pan mixer machine is composed of a feeding cylinder, main mixing shaft, machine rack, motor, cyclical reducer, rotating arms, stirring spades, etc. The motor is installed vertically. The machine rack is fabricated with abrasion-resistant steel. These vertical pan mixers are ideal for the efficient and thorough blending of solids and bulk powder materials. The blending action is far gentler than that of horizontal blenders, making it more suitable for delicate and abrasive applications.

Parameter of Vertical Pan Mixer:

| Name | Model | Dimension (CM) | Production capacity (t/h) | Power (Kw) |

| L*W*H | ||||

| Pan Mixer | YPJB-1500 | 160X160X155 | 2-4 | 7.5 |

| YPJB-2000 | 210x210x160 | 3-6 | 11 |