The rotary drum screener is a new type of self-cleaning sieve special equipment after the relay vibrating screen and the common mesh roller screen. This series of roller-type sieving machines is a commonly used fertilizer production equipment or in commercial compost facilities, which is mainly used for separating the finished product and returning material, can also classify the product, to get a uniform classification of finished products. The machine adopts a combined type of screen mesh, convenient for servicing and changing. The rotary drum screen has the advantages of simple structure, convenient operation, and stable working, it is the ideal equipment for compound fertilizer, organic fertilizer, and powder fertilizer production.

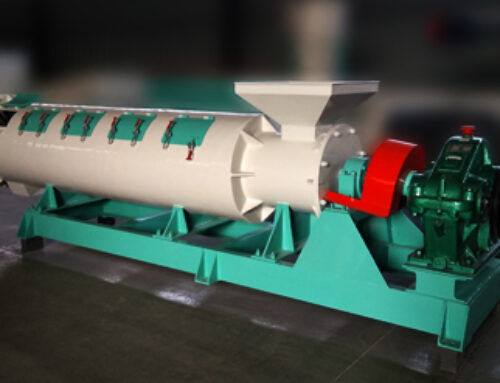

Three main parts of the rotary screen

- Frame: the machine frame is made of the excellent carbon steel plate and channel steel, the purpose of this machine has been achieved through strict product qualification and specific process requirements.

- Rotating screen: this part uses the combined type of screen mesh, which is transmitted to the main shaft by a transmission wheel through a coupling. The screen is installed and welded on the rolling cage of the main shaft. The material enters from the feeding end, continuously rotating and graded in the rolling cage, then uniformly flows out from the bottom of the material outlet. It can effectively separate the finished product from the material to improve work efficiency.

- Transmission connecting part: the driving motion of the motor-driven pulley, V-belt, and reducer makes the chief axis rotate and operate. The drive speed reducer and the main engine adopt shaft pin type coupler phase tooth transmission, convenient for assembly and maintenance.

Working principle of the rotary compost screen

The rotary drum screen is composed of a round or hexagonal roller, frame, hopper, reducer, drive motor, and auxiliary structure. The material to be graded is fed into a revolving screen from the organic fertilizer granulator, screw pushed inner screen. In the process of rotating in the inner and outer screen, semi-finished products can be divided into standard particles, large particles, and fine particles, to achieve a variety of particle classifications.

Applications of the rotary sifter

The drum screen has a wide range of applications, not only suitable for dry sieving but also suitable for various wet sieving; it is not only suitable for the screening and selection of various coarse grain grade materials but also suitable for the screening of various medium and fine grade materials. Moreover, by adding necessary auxiliary devices such as a cleaning net, it can solve the problem of clogging in fine screening. In addition, by adding a sealing device, the roller screen can also solve the dust pollution problem in screening operations.

Advantages of the rotary screener

- Wide adaptability: roller screen is widely used in all kinds of material screening, whether it is fertilizer particles, wood pellets, and other coal materials, all can be successfully screened.

- The feeding way is simple and diverse: the roller screen feeding mouth can be designed according to the actual site, and whether it is a belt, funnel, or other feeding methods, it can be smooth feed without taking special measures.

- High screening efficiency: because the device is provided with a plate cleaning mechanism, in the process of screening, regardless of material viscosity, humidity, and miscellaneous, they will not plug the screen through the relative motion of the screen scarifier and the body, thereby improving the efficiency of screening equipment.

- Large screening quantity: in the same size, the area of the circle is larger than that of other shapes, and the effective screening area is large so that the material can fully contact the screen mesh.

- Low energy consumption: the power of the drum screen motor is small, it is 1/2 to 1/3 of the other type of screen.

- Good working environment: the whole sieving cylinder can be sealed with a sealed isolation cover, which completely eliminates the phenomenon of dust flying in the process of screening.

- Low noise: because the rotary speed is small, and the sealed isolation cover is isolated from the outside, the noise can not be transferred to the outside in the operation, thereby reducing the noise of the equipment.

- Long service life: the drum screen is composed of a plurality of circular nets, The total screening area is much larger than that of other types of sieves, coupled with high efficiency. Equipment running time is short, so the service life is longer.

- Convenient maintenance: an observation window is arranged on both sides of the equipment sealing dustproof cover, so the staff can observe the operation at any time.

| Name | Model | Dimension (CM) | Capacity

(t/h) |

Power (Kw) |

| L*W*H | ||||

| Rotary Screen Sifter | GTSF-1.0X3 | 380x130x260 | 1-3 | 3 |

| GTSF-1.2X4 | 500x160x300 | 2-5 | 5.5 | |

| GTSF-1.5X5 | 630x188x345 | 3-7 | 7.5 |