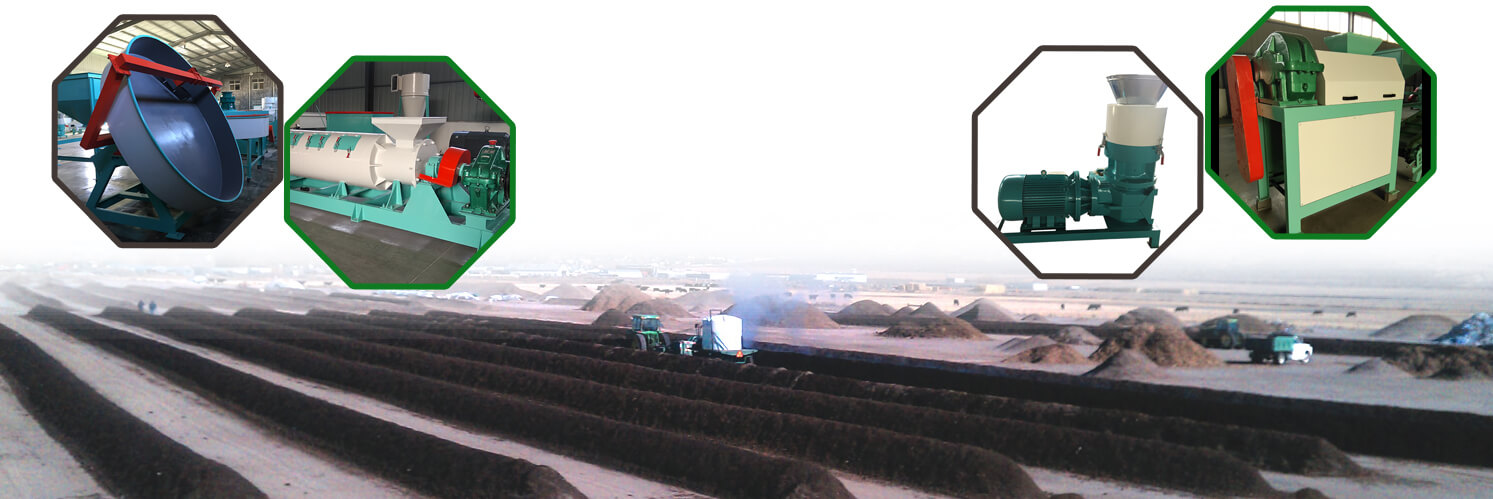

Innovative Organic Fertilizer Machines

We are dedicated to the quality manufacturing of organic fertilizer making machines, providing not only complete sets of organic fertilizer machines but also complementary services. Offer you a complete organic fertilizer production solution.

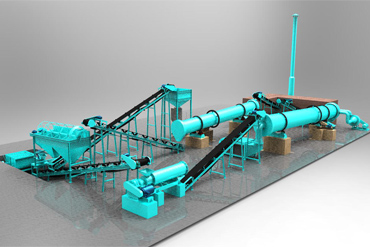

This organic fertilizer production line pelletizes animal manure (cow dung, chicken manure, pig manure) into nutrient-rich organic fertilizer pellets. It can meet most investors’ organic fertilizer production demands. The whole process includes crushing, fermenting, mixing, granulating, packaging, screening, drying, cooling, and granule polishing.

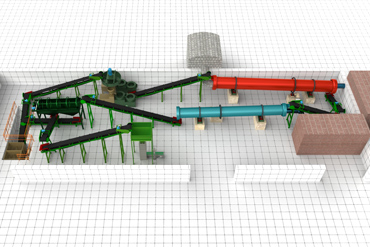

This turnkey organic fertilizer production line includes all necessary fertilizer machines, from raw materials crushing, composting, mixing, granulating, drying, cooling, screening, and packing. This is a medium-scale production plant (20,000 tons annually output) that can completely satisfy the production requirement for investors who wish to start an organic fertilizer production on a medium scale as a beginner business at an affordable cost.

This small-scale organic fertilizer plant provides profitable organic fertilizer manufacturing business ideas for a new investor. Its production capacity is 500-1000kg per hour. It is wiser to choose a small-scale plant that is simple to start and manage without too much stress and trouble. What is more, this small-scale organic fertilizer plant is with a very low initial investment.

About The Organic Fertilizer Machines

GET A QUOTE

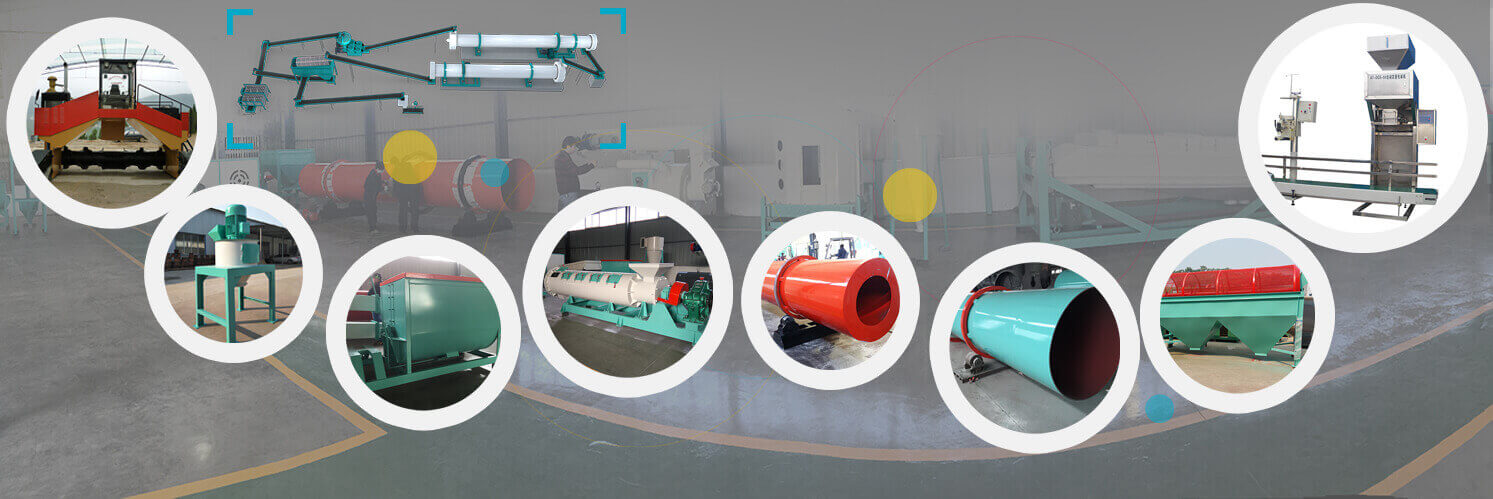

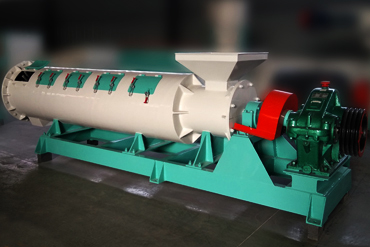

This organic fertilizer granulator owns the highest granulation rate among all the organic fertilizer granulators, achieving a super-efficient fertilizer granulation process in large-scale organic fertilizer production lines. The raw materials do not need to be dried and crushed before granulation. It has a specialty for organic fermentation fertilizer granulation of livestock manure, pile retting fertilizer, green manure, cake fertilizer, peat, soil miscellaneous fertilizer, microbial, and other municipal solid waste.

The Hydraulic compost turner is a kind of commercial composting equipment used in windrow composting systems, and the hydraulic windrow turner is the best-selling. We provide 3 types of windrow turners here: fully hydraulic compost turners, hydraulic auxiliary crawler windrow turners, and hydraulic auxiliary wheel compost windrow turners. They differ in production capacity and driven assembly. The whole fermentation time can reduce to 7-15 days by composting organic waste with hydraulic compost windrow turners

This groove-type compost turner is a small-scale poultry composting machine, also called a pile-turning machine, mainly used in indoor manure fermentation/composting systems. It can ferment all kinds of biodegradable organic wastes, most widely-used in poultry manure treatment systems to fully compost cow manure, chicken manure, pig manure, etc. Its working distance can reach 10 meters, and the daily composting capacity of this machine is about 80-160 square.

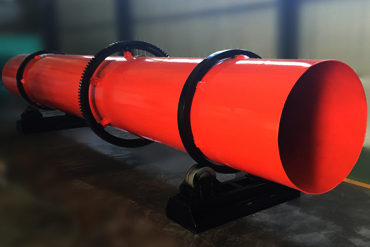

In organic fertilizer production, material needs to be dried to remove water from solid organic fertilizers. Rotary drum fertilizer dryers are to reduce the moisture content in the organic fertilizer industry with exhaust air control. Simple operation, low energy consumption, long lifespan, even drying, and easy maintenance.

This high-moisture organic waste crusher can shred green waste, food waste, biomass waste, animal manure, and slaughterhouse waste to produce compost and organic fertilizer. It is a popularly used crusher machine in organic fertilizer production. Generally speaking, a crusher can reduce the volume by up to 50% which greatly speeds up organic waste’s composting process by 10 times.

This automatic fertilizer packager can achieve quantitative & high-speed bagging of powders, granular products (organic fertilizer, etc.), and flakes. This fertilizer packing machine featured convenient operation, accurate weighing, fast packaging speed, and high packaging accuracy, it is able to save 1/3 of the operating time.

Request A Free Quote

We are glad to help with your organic fertilizer project. Please fill out the below form to let us know your requirements, we will contact you as soon as possible.