ASK & WE ANSWER

FREQUENTLY ASKED QUESTIONS

Frequently Asked Questions

◆ Market study – analyzing target market and organic fertilizer market trends in your country/local (past supply & present demand);

When it comes to selling organic fertilizer, there is indeed a large market. In essence, your target market can’t be restricted to just farmers who are strictly cultivating organic crops, but all those who have been involved in any form of crop cultivation; deciding your annual production quantity based on the present market demand indicated in your market analysis and considering the technological aspect of the project. Usually, an organic fertilizer plant operates double shifts 16 hours a day and 300 days a year.

◆ Site selection

Virtually every aspect of organic fertilizer production and marketing will, at least in part be affected by the choice of the plant site. Proper site selection is a prerequisite to the establishment of safe and effective composting operations. Site selection criteria:

◇organic fertilizer factory sites should be located at such a distance to ensure that there will not be any potential adverse impacts from compost site runoff into surface waters and to promise that the smell of manure fermentation won’t affect people in residential areas.

◇accessibility to customers, suppliers (of raw materials and supporting services), & workers.

◇transportation infrastructure (roads, rail, etc.) and utilities (water, power, and energy supplier).

◇affordability of land, rent

◆ Inputs raw & auxiliary materials

The best material used to make organic fertilizer includes animal wastes from meat processing, peat, manure, slurry, food waste, plant wastes from agriculture, treated sewage sludge, paper scraps, olive leaves, palm oil waste, biogas waste, vinegar residue, sugar mill waste, etc.

◆ Organic Fertilizer Equipment purchasing

◆ Finished organic fertilizer distribution and how to promote your organic fertilizer

For new starters, they would choose a small organic fertilizer plant. To save costs and decrease the occupation space, therefore, some processing machines, such as dryers, and coolers, could be “removed” from the plant layout.

Generally speaking, the organic fertilizer production process includes:

Organic materials crushing (chain crusher) → composting (compost turner) → mixing compost with other ingredients (horizontal blender) → granulation (organic fertilizer granulator) → drying (rotary dryer) → cooling (rotary cooler) → sieving (rotary screen) → packaging (automatic fertilizer packager)

Take a small-scale organic fertilizer production plant (pan granulation production line with an annual output of 5000 tons) for example.

◆ Space needed as below:

Fermentation stage: 20*5m

Granulating stage: 40*18m

◆ It is an auto-processing line. 4 workers are enough to operate and keep the continuous production of organic fertilizer.

◇1 worker for compost turner operation in the fermentation stage

◇1 worker for feeding raw material

◇1 worker for the packing machine

◇1 worker for the control cabinet

◆ For installation, here are two operations:

option 1: buyer install themselves. We provide factory design and layout.

option 2: we can send 2 engineers for installation, commissioning, and training. Buyers should bear visa fees, round tickets, accommodation, etc. with a salary of 150USD per day per engineer. It will take about 20 days to finish the installation and training.

The life span of the main part in the organic fertilizer machine will be 5-8 years, if keep better maintenance, can last for 8-10 years.

The main body (not including the wearing parts) guarantee is one year. During the guarantee period, if the machines are broken without any artificial factors, we will repair the machine for free.

We will provide the spare parts for you at any time.

◆ Composting process: 7-10 days (depending on the local temperature, raw materials, and compost turner). The compost turner with larger output is available to keep the continuous working of the factory.

◆ The organic fertilizer granulation machine with proper production capacity will be chosen for you so that it will achieve continuous granulation and satisfy customers’ requirements on output every day.

45% fruits and vegetable wastes, 30% sewage sludge, 20% agricultural wastes or sawdust, and 5% other nutrients.

The moisture content of the materials should be under 60%. If above 60%, a solid-liquid dewatering machine is required to lower the MC.

1 ton of raw material with 50% moisture content will bring 0.85 tons of final products.

1.2-1.5 tons of raw materials need to be fed in one hour.

GET QUOTE

Fill in the form below to request a quote to discuss your fertilizer project.

Complete Organic Fertilizer Solutions

Customized Compost Fertilizer and Granular Organic Fertilizer Manufacturing Plant

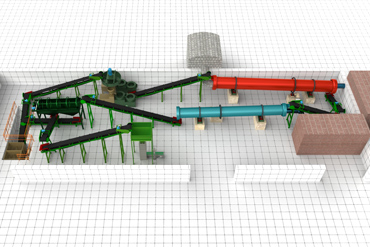

This organic fertilizer manufacturing plant can produce both powder compost fertilizer and granular organic fertilizer which satisfy different customers' demands for finished products. The whole line is equipped with high-efficiency fertilizer-making machines to promise continuous production. Powder organic fertilizer production process: composting-crushing-sieving-packaging. Granular organic fertilizer: mixing-granulation-drying-cooling-screening-packaging. The organic fertilizer production line will be customized according to your requirement and your local conditions. We will offer you a complete organic fertilizer production solution.

Organic Fertilizer Pellets Extrusion Line with a 30,000 Tons Annual Output

This organic fertilizer production line pelletizes animal manure (cow dung, chicken manure, pig manure) into nutrient-rich organic fertilizer pellets with an annual output of 30000 tons. It can satisfy most investors’ organic fertilizer production demands. The whole process includes crushing, fermenting, mixing, granulating, packaging, screening, drying, cooling, and granule polishing. The flat die organic fertilizer pellet mill is installed to complete the whole pelletizing process. So We call this plant a Flat-die Fertilizer Production Line. The output fertilizer pellets are popularly used in agricultural production companies, independent farmers, golf courses, and commercial landscapers can use those organic manure fertilizer pellets.

Small Scale Organic Fertilizer Plant – 800 kg/h

Organic fertilizer is one of the most important agricultural inputs. This small-scale organic fertilizer plant provides profitable organic fertilizer manufacturing business ideas for a new investor. Its production capacity is 500-1000kg per hour. Through the organic fertilizer production process (organic fertilizer machine), make organic fertilizer pellets or granules using livestock and poultry manure, straw, rice husk, biogas, sludge, food waste, and urban waste, both to reduce environmental pollution and reuse organic matter. It is wiser to choose a small-scale plant that is simple to start and manage without too much stress and trouble. What is more, the small-scale organic fertilizer plant is with a very low initial investment.

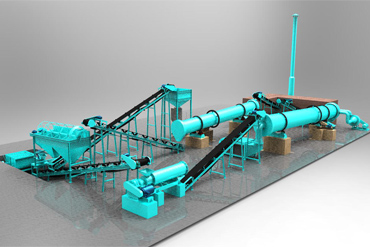

3-5 T/H Organic Fertilizer Production Line

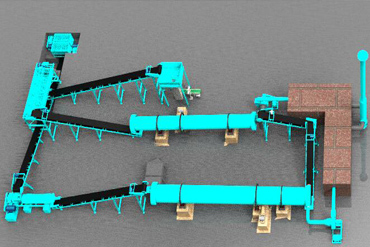

It is a turnkey organic fertilizer production line, from start to finish. This plant includes all necessary processing machines in a complete production line, from raw materials crushing, composting, mixing, granulating, drying, cooling, screening, and packing. All fertilizer equipment is placed/installed in the proper place and right operational sequence to keep a continuous, high-efficiency production. If you are interested in developing your business by using organic waste to produce organic fertilizer, this plant will be a better choice. It is a medium-scale production line with economical cost. This is a medium-scale production plant (20,000 tons annually output) that can completely satisfy the production requirement for investors who wish to start an organic fertilizer production on a medium scale as a beginner entrepreneur.

Request A Free Quote