Horizontal organic fertilizer blender is a proven design for fast, accurate mixing of small amounts of crushed organic materials in a batch to provide a uniform, homogeneous mix. As mixing and blending of bulk solids occurs frequently in many industrial processes, such as organic fertilizer production, the continuing demand for high-quality fertilizer blender/mixer that is capable of fast blend times, equipment flexibility, ease of cleaning, and assurances that demixing. That is exactly the highlight of Horizontal Blender. This organic fertilizer blender machine improves blend uniformity and decreases cleaning time between batches.

Design and Construction of horizontal-type organic fertilizer blender:

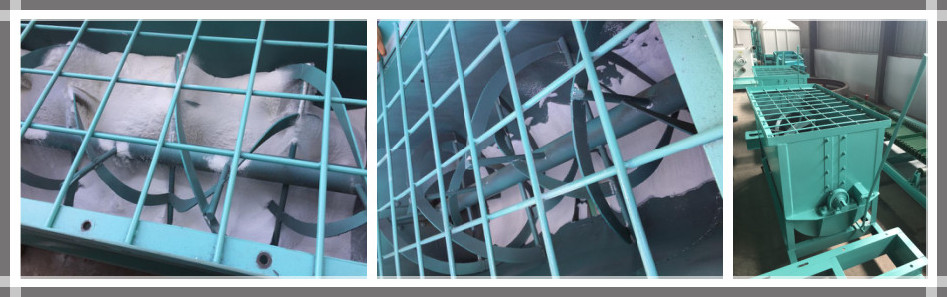

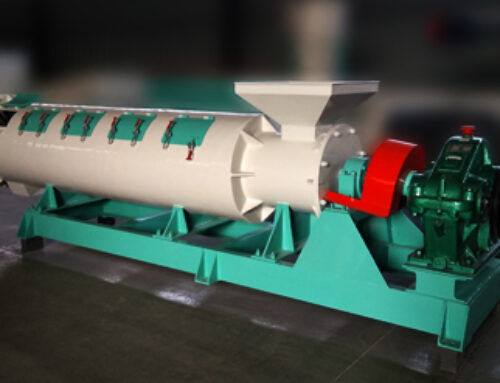

This fertilizer blender consists of a U-shaped horizontal trough and a specially fabricated paddle-type agitator. Every particle of material is subjected to agitation during loading, blending, and discharge. The agitator consists of a set of inner and outer helical agitators. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. After the organic fertilizer materials are fully mixed, open the discharge port under the tank and the materials will be discharged from the blending equipment and conveyed to the organic fertilizer granulator.

Features of Horizontal Fertilizer Blender

▲ With a reverse-spiral design, the agitator delivers uniform, high-capacity blending at low power cost.

▲ Paddle assemblies mix using a tumbling motion and have less product shearing during the process.

▲ Its reasonable design makes this blender machine available in both organic fertilizer plants and compound fertilizer factories.

▲ Compared to verticle fertilizer mixers, horizontal ones are with smaller mixing capacity, which makes them suitable for both commercial use and home use.

Other features: sturdy construction, minimal maintenance required, consistent functioning, etc.

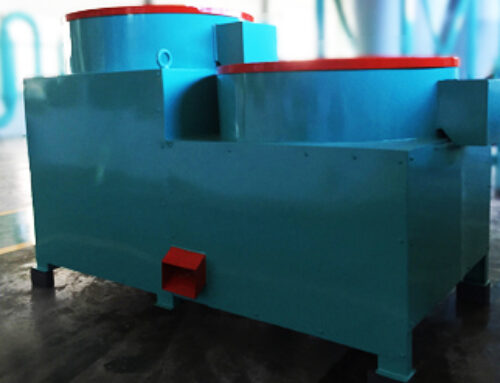

PS: In an organic fertilizer production line, we usually recommend customers install 2 sets of mixer machines (one is for mixing, the other for discharging) to promise continuous functioning.

The Problem, Possible Cause, and Solution in the Running of Horizontal Organic Fertilizer Blender:

| PROBLEM | POSSIBLE CAUSE | SOLUTION |

| The motor cannot start normally | low voltage | Start the motor when the voltage has stabilized |

| Short circuit of the motor | Check or replace the motor | |

| Reducer has an abnormal sound | Lack of oil | add lubrication |

| Reducer wear out | Check or replace the reducer | |

| Non-uniform mixing | Blend time being too short | Keeping blending to keep a uniform, homogeneous mix |

| Rotating paddles damages | Replace new paddles | |

| The ingredients sticking to the wall | The materials with high moisture content | Lower the MC |

| Gaps between paddles and walls are too large | Replacing new paddles to shorten the distance |

Technical Parameter:

| Name | Model | Dimension (CM) | Production capacity (t/h) | Power (Kw) |

| L*W*H | ||||

| Horizontal Blender | WSJB-70 | 233X113X97 | 2-3 | 11 |

| WSJB-90 | 233X107X120 | 3-5 | 15 |