Unlike the chemical kind, organic fertilizers feed soil organisms in addition to your plants, helping to build healthy soil-not destroy it. Therefore, bio-organic fertilizers always have business opportunities, and fortunately, there are more and more truly organic fertilizers coming onto the market. Organic fertilizer business is a worldwide big business: The application or supply of chemical fertilizer is slowly controlled and restricted by the relevant authorities of most countries and this will be a great business opportunity for an organic fertilizer plant.

Solid fertilizer is typically granulated or powdered. Here in this article, we will introduce powdered organic fertilizer-making technology, and how to further process powder ones into granular organic fertilizer!

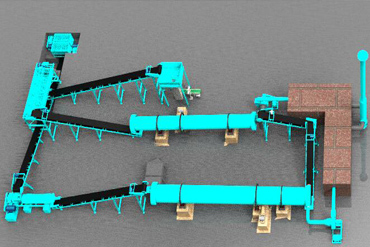

◆ Powder/Compost Fertilizer Production Line:

We know that any organic materials can be processed into organic compost fertilizer. Actually, after the crushing and screening process, compost becomes a high-quality and sellable powdered organic fertilizer. That is to say, if you want to manufacture organic fertilizer powder (for example, neem cake powder, coco peat powder, oyster shell powder organic fertilizer, dry cow dung powder organic fertilizer, etc.), the necessary process includes: fully composting the materials, crushing the generated compost, and then sieving and packing them.

Organic materials are piled into two large windrows aerating them periodically by mechanically turning the piles. A hydraulic compost turner is used in this powder fertilizer production line for windrow composting. It is suited for turning large volumes of piles such as that generated by entire communities and collected by local governments and high-volume food-processing businesses.

There are several parameters affecting the composting process, separately particle size, C: N ratio, moisture content, oxygen content, and temperature. Notice should be taken in the whole composting process:

- Crushing materials into small particles;

- A C:N ratio of 25-30:1 is optimum for efficient composting. The more varied the materials going into the pile, the better chance of maintaining the proper C:N ratio and efficient decomposition;

- The best water content of composting raw materials is usually around 50%-60%; pH controlled at 5.0-8.5;

- Turning will release the heat of compost piles. When the material is actively decomposing, the temperature, which falls slightly during turning, will return to the previous level in two or three hours. That is one of the powerful advantages of compost turners.

–Crushing–

Half-wet crusher machine is utilized for crushing the compost. Disintegrating clumps in the compost by crushing or grinding prevents problems that may occur when the organic compost fertilizer is packaged.

–Sieving–

Sieving of the compost to obtain different fractions for marketing or to remove impurities. This production process is largely mechanized around a rotating sieving machine with a medium-large mesh size. In front of the sieving machine, a 12-ton collector bucket is filled after which a conveyor belt transports the rough compost into the sieving machine. Therefore, a rotary drum screen is essential to prepare the compost for transport, storage, sale, and application. Sieving improves the structure of the compost for packaging, and mechanical removal of impurities improves the quality of the compost before marketing or use.

–Packaging–

Subsequently, the sieved compost is packed in 25kg/50kg bags and temporarily stored until the moment of dispatch.

By windrow turning, crushing, sieving, and packing, compost becomes a commodity for sale.

Technical Parameter of Compost Fertilizer Production Line:

| Name | Model | Dimension(CM) | Production Capacity(t/h) | Power(Kw) | Quantity (set) |

| L*W*H | |||||

| Hydraulic compost turner | FD300 | 342x400x340 | 1000-1200 m3/h

|

93 | 1 |

| Half-wet crusher machine | BSFS-60 | 148X124X126 | 2-4 | 15×2 | 1 |

| Rotary screen | GTSF-1.2X4 | 500x160x300 | 2-5 | 5.5 | 1 |

| Automatic packager | DGS-50F | 3-8bag(s)/minute | 1.5 | 1 |

The necessity to granulate powder compost fertilizer into granular ones:

Powder fertilizers are always sold in bulk at cheaper prices. Further processing powder compost can add its nutritional value by mixing other ingredients such as Humic Acid, benefiting both buyers (promoting crop growth with a higher nutrition content) and investors (selling them at a more reasonable price).

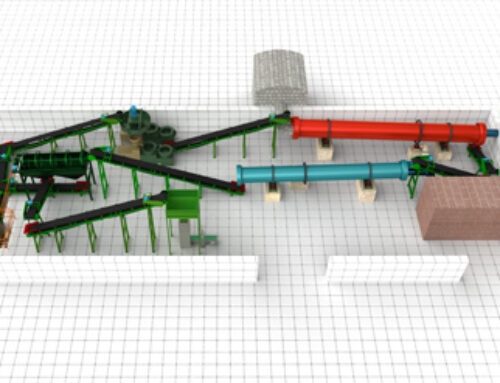

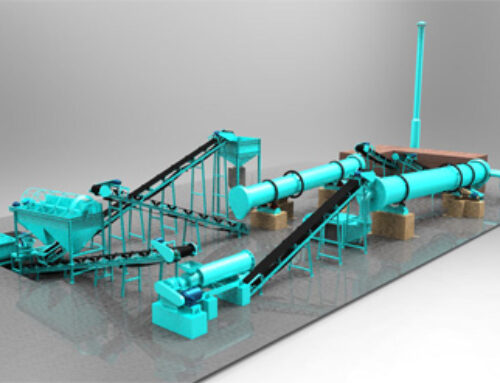

–Mixing and Granulation–

In the mixing process, you can blend compost powder fertilizer with whatever ingredients you want to increase its nutritional value. Then granulating the mixture with Organic Fertilizer Granulator. Organic fertilizer Granulation serves to produce dust-free particles of controlled size and shape. The wet type granulation is featured the closed granulating process (no emission of respirable dust), large production capacity, and short process time.

–Drying and Cooling–

Drying is used in practically every plant that manufactures solid materials, in the form of powders and granules. Drying reduces the moisture content of the generated organic fertilizer granules while cooling decreases the hot temperature to 30-40℃. Rotary dryers and rotary cooler machines are installed in commercial granular organic fertilizer production lines.

–Screening and Packaging–

Organic fertilizer granules should be screened to obtain the desired particle sizes and to remove the product size fraction. Rotary screen is commonly used in the fertilizer production plant, mainly for the separation of products,

but also to achieve the finished grade, finished evenly to classification. After the screening, Organic fertilizers with uniform size are

Benefits of the Generated Granular & Powder Organic Fertilizer?

Fertilizers come in either a solid (granular or powder form) or liquid form. Granular, or powder, organic fertilizers are commonly used to amend the soil with organic material which gives a desired nutritional value or other beneficial effects. They can also break down quickly when worked into the soil for quick nutrient release. These last longer than liquids because the solid is absorbed in a slower rate and doesn’t need to be applied as often.

Using slow-release organic granular fertilizer significantly decreases the chances of damaging lawns and plants.

Technical Parameter of Granular Organic Fertilizer Production Line:

| Name | Model | Dimension (CM) | Production Capacity (t/h) | Power (Kw) | Quantity (set) |

| L*W*H | |||||

| Horizontal blender | WSJB-90 | 233X107X120 | 3-5 | 15 | 2 |

| Newly-developed organic fertilizer granulation machine | JCZL-60 | 355x143x98 | 2-3 | 37 | 1 |

| Rotary dryer | HGJ-1.2 | 1300x236x180 | 2-3 | 7.5 | 1 |

| Rotary cooler | LQJ-1.2 | 1300x236x180 | 3-5 | 7.5 | 1 |

| Rotary screen | GTSF-1.2X4 | 500x160x300 | 2-5 | 5.5 | 1 |

| Automatic packager | DGS-50F | 3-8bag(s)/minute | 1.5 | 1 | |

| Chain crusher | LSFS-60 | 100X73X170 | 1-5 | 15 | 1 |