Introduction of Organic Fertilizer Disc Granulator

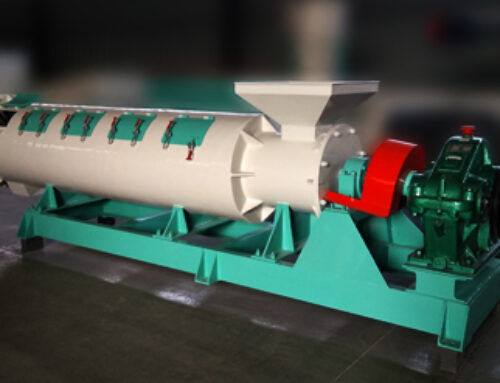

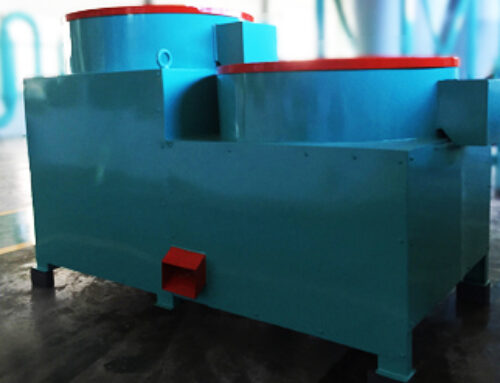

With an arc structure and sturdy materials, a disc granulator, also called a disc pan granulator or pan granulator, makes the granulation rate up to 93% or more. Adopting flexible belts to transmit, reduction gear and electric motor start steadily, slowing down the impact force and increasing the service life of the equipment. Moreover, there is no need to use a foundation bolt to fix the equipment for the base of the machine is designed with thickened, aggravated, and solid materials. Due to its simplified structure, steady running, and long lifespan, our disc granulating machine is sturdy and durable and has uniform granulation and a high granulation rate, becoming the popular and ideal choice of many industries.

Disc Pan Granulation Process

The granulation process of disc granulators is granulating by giving adequate water content and binder to powered materials in the titled rotating pan. To be specific, a variety of dry powder materials are added from the top of the equipment, pre-compressed, and transferred into the pelleting disc, after uniform adhesion, constant rotating, and spraying device, forming into ball shape pellets. In order to prevent materials from adhering to the wall, we also design the automatic removing mixture device within the upside of the granulating disc, thereby prolonging the service life of the granulating machine.

Advantages and Applications of Disc Pan Granulator:

- With a new design and reasonable structure, it is convenient and flexible to arrange.

- The machine can be widely used in a variety of applications with different raw materials, such as compound fertilizer, feeding stuff, chemical engineering, metallurgy, and so on, and can produce various concentrations and types of compound fertilizer, including inorganic fertilizer, bio-fertilizer, and magnetic, organic fertilizer production, etc.

- Without industrial residue emission, pan granulator is environmentally friendly, and due to low investment and quick returns, it also has good economical benefits.

- With effortless simple maintenance and operations, raw materials can be made quickly and easily to the granulation process while the pan granulator is in operation.

Technical Parameter of Disc Pan Granulator:

| Name | Model | Dimension(CM) | Capacity (t/h) | Power (Kw) |

| L*W*H | ||||

| Pan Granulator | YPZL-2000 | 235x185x220 | 0.75-1.5 | 7.5 |

| YPZL-2500 | 288x218x250 | 1-2 | 11 | |

| YPZL-3000 | 342x248x287 | 1.5-3 | 11 | |

| YPZL-3200 | 360x270x320 | 2-4 | 15 |