Groove type compost turner, also called pile turning machine, is widely used for making organic fertilizer through fermenting and composting the organic wastes (such as livestock manure, sludge and garbage, filter mud, straw, and so on). As everyone knows, the most headache problem for livestock and poultry farmers is how to deal with animal excrement properly without polluting the environment or bringing foul smell during the season no need to apply fertilizer.

Fortunately, our compost turner is just in time, which can not only solve this puzzle and reduce environmental pollution but also turn waste materials into wealth and provide high-quality organic fertilizer for agriculture. Because of its excellent composting performance, this machine has been extensively applied for the fermentation and composting of organic fertilizer plants, compost fertilizer production lines, garden spots, Agaricus bisporus plantation, and so on.

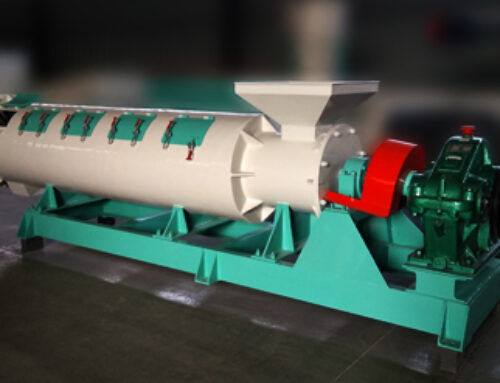

General Configuration of Poultry Composting Machine

- Power transmission device: this unit consists of an electric motor, reduction gears, chain wheel, shaft block, and principal axis, which is an important device providing power for composting turners.

- Running gear: this unit consists of a walking motor, transmission gear, transmission shaft, and walking sprocket wheel.

- Lifting device: this unit consists of a winding engine, shaft coupling, transmission shaft, and bearing block.

- Composting device: this unit consists of the sprocket, support arm, and turning rollers.

- Transfer device: this unit consists of a walking motor, transmission gear, transmission shaft, and moving wheel, providing a temporary transport tool for the compost turner when changing the groove.

Highlights of Groove Type Compost Turner

- With strong and durable material and structure, this compost turner machine has high efficiency, smooth operation, and uniform turning. Moreover, it has low energy consumption and excellent composting performance because of adopting groove type operating mode. With sturdy turning rollers, this machine can also crush and mix raw materials to some extent.

- Suitable for aerobic fermentation, this machine can cultivate and reproduce microorganisms quickly. And raw materials after crushing would not generate a foul smell and anaerobic zone. What’s more, organic fertilizer produced by our groove-type compost turner can reach high-quality fertilizer standards, and would not rise to the phenomenon of seedling burning when used on agricultural products.

- As the most functional pool-type continuous compost turner, its working distance can reach 10 meters and the fermentation period is about 7-8 days. Furthermore, the daily composting capacity of this machine is about 80-160 square while its annual production is about 10,000-20,000 tons.

Technical Date of Groove Type Commercial Compost Machine

| Model | FJ6000×1050 | FJ6000×350 | FJ4000×1050 | FJ4000×350 |

| Matched power(kW) | 25.74 | 41.5 | 10 | 10 |

| Working speed(m/h) | 50 | 50 | 50 | 50 |

| No-load speed(m/h) | 100 | 100 | 100 | 100 |

| Size of the fermentation tank (w×h )mm |

6000×1050 | 6000×350 | 4000×1050 | 4000×350 |

| External dimension (mm) L×W×H |

4670×3920×2740 | 4670×4800×3200 | 4670×3920×2740 | 4700×4800×3200 |

| Lift height of gear(mm) | 1400 | 1500 | 1400 | 1500 |

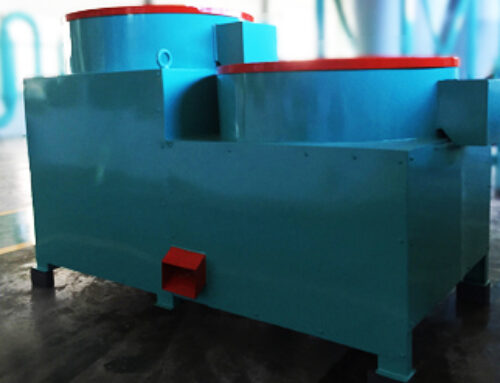

Technical Date of Hydraulic Groove Type Compost Turner

| Model | XSCSFD03 | XSCSFD04 |

| Power(kW) | 15.5 | 22.75 |

| Working speed(m/minute) | 50 | 50 |

| Size of fermentation tank(w*h )mm | 3000×700 | 4000×900 |

| Lift height of mixing gear(mm) | 700-1000 | 800-1100 |