“Dear sir, greetings. We are Oman-based individuals and would like to start up an organic fertilizer plant in Oman with a capacity of 20,000 tons per year. We have gone through your company profile and it is exactly meeting our requirements and is very much informative and impressive. We are in need of a complete techno-commercial proposal for 20000 tons per year to get approval from related ministries in Oman. We are really aggressive and we have enough land here to start up a plant at the earliest. ”

The Oman customer shows great interest in getting more high-value information about a complete organic fertilizer production line with a 20,000 tons annual capacity. A 3-5 T/H production plant will exactly satisfy this production requirement by 6000 annual working hours.

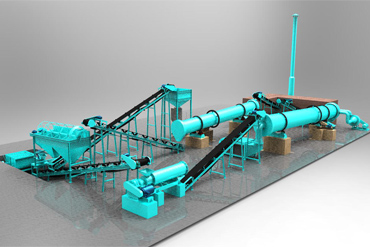

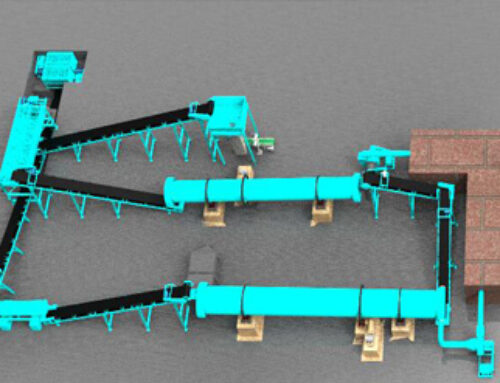

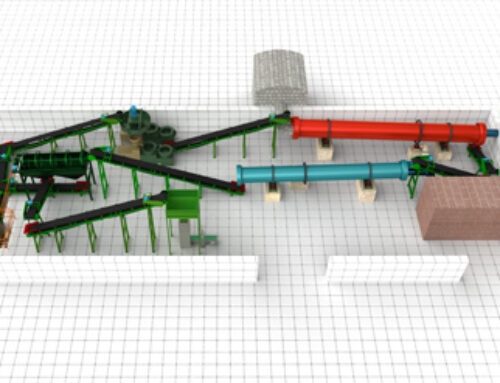

What Equipment Does the 3-5T/H Complete Organic Fertilizer Plant Exactly Include?

We know organic raw materials, for example, animal dung, soya bean waste, organic municipal waste, farm waste, food waste, etc. really vary with different customers from different areas. One thing however we can make sure of is that the technological process of organic fertilizer keeps the same in essentials while differing in minor points. This 20,000 T/Y fertilizer production plant consists of:

This compost turner is often used in under-house composting in poultry operations for fly control and mixing. The moisture content of materials should be 55-65%.

- Working process: organic materials are placed in the fermentation tank above which there is the compost turner. If your materials are mainly animal manure, please notice the C/N ratio, add green waste to balance the ratio=30:1 or 25:1

- Turning the organic material periodically(2-3 times each day). Frequent turning will help speed up the composting process.

- Horizontal blender – Model WSJB-90

Two sets of horizontal-type blenders are installed in the production plant to provide a uniform mix. We all know that almost any organic material is suitable for composting, and a compost pile needs a proper ratio of carbon-rich materials and nitrogen-rich materials. That is to say, organic materials used for compost should include a mixture of brown organic material (dead leaves, twigs, manure, etc. supplying carbon) and green organic material (lawn clippings, fruit rinds, etc. supplying nitrogen). Therefore, horizontal blender machines become inevitable. It also can be used to blend fertilizer components together in inorganic fertilizer production.

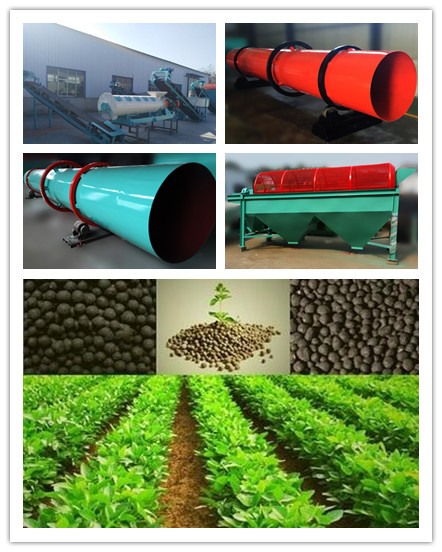

- Organic fertilizer granulation machine – Model JCZL-80

In this organic fertilizer production line, compost is converted into a more usable form by granulating it. Organic fertilizer granules granulated by a wet-type granulation machine are spherical in shape for commercial use. Because of the latest and humanity machine design, the fertilizer granulator saves energy & costs, much easier to operate. It achieves a material granulation process in a reasonable and thorough manner. The whole production process is smooth, simple, and environment-friendly.

- Organic fertilizer rotary dryer machine – Model HGJ-1.2

Adjustment and control of moisture levels in solid fertilizer through drying is a critical process in commercial organic fertilizer manufacturing. A rotary dryer is employed to minimize the moisture content (MC) of fertilizer granules by bringing them into direct contact with a heated gas. Solid fertilizer is transported into its inclined cylindrical long drum inside which is fitted with internal flights. The flights lift organic fertilizer granules upside down to lower their MC.

- Rotary cooler – Model LQJ-1.2

After drying, organic fertilizers are at a rather high temperature-70-80℃. The rotary cooler is used to cool the granules to normal temperature rapidly. In the 3-5T/H complete fertilizer production line, it is installed behind the dryer machine for continuous production.

- Rotary screen – Model GTSF-1.5X5

A rotary drum screener with good performance is installed in this production line to obtain organic fertilizer granules with the desired particle sizes and to remove the product size fraction. Over-sized fertilizers are re-crushed by a chain crusher (Model LSFS-60) and recycled to the granulator along with the undersized ones. Organic fertilizer with uniform particle size will be further transported to the packager machine (Model DGS-50F) for bulk bagging and for sale.

Why do we Recommend you Choose this 3-5T/H Organic Fertilizer Production Line?

★ This plant includes all necessary processing machines in a complete production line, from raw materials crushing, composting, mixing, granulating, drying, cooling, screening, and packing. All fertilizer equipment is placed/installed in the proper place and right operational sequence to keep a continuous, high-efficiency production.

★ It is a medium-scale production plant (20,000 tons annually output) that can completely satisfy the production requirement for investors who wish to start an organic fertilizer production on a medium scale as a beginner entrepreneur. What is more, we provide not only fertilizer production machines but detailed local market analysis and the best advice on how to begin a fertilizer business.

★ All details, such as working videos, factory layout photos, machine prices, plant costs, and project reports, are well-packed. They can be sent directly to your email box at once and right now.

★ The production plant has low demand for organic materials. It can process organic manure, municipal solid waste, food waste, biogas residue/digestate, bagasse, coffee grounds, leaves, vegetable waste, maize husk, household garbage, agriculture wastes, slaughterhouse wastes, etc.

Technical Parameter:

| Name | Model | Dimension (CM) | Production Capacity (t/h) | Power (Kw) | Quantity (set) |

| L*W*H | |||||

| Horizontal blender | WSJB-90 | 233X107X120 | 3-5 | 15 | 2 |

| Newly-developed organic fertilizer granulation machine | JCZL-80 | 416x166x117 | 3-5 | 55 | 1 |

| Rotary dryer | HGJ-1.2 | 1300x236x180 | 2-3 | 7.5 | 1 |

| Rotary cooler | LQJ-1.2 | 1300x236x180 | 3-5 | 7.5 | 1 |

| Rotary screen | GTSF-1.5X5 | 630x188x345 | 3-7 | 7.5 | 1 |

| Automatic packager | DGS-50F | 3-8bag(s)/minute | 1.5 | 1 | |

| Chain crusher | LSFS-60 | 100X73X170 | 1-5 | 15 | 1 |