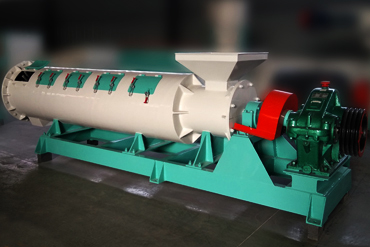

Wet Type Organic Fertilizer Granulation Machine Overview

The wet-type organic fertilizer granulator achieves a super-efficient fertilizer granulation process in large-scale organic fertilizer production lines. It owns the highest granulation rate among all the organic fertilizer granulators, which convinces the manufacturers that this machine is right for them.

The granulated organic fertilizer-making machine reduces environmental pollution, is safe and non-toxic to humans, animals, and the environment, and is an environment-friendly fertilizer. Therefore, it is favored by most investors in the fertilizer industry.

The wet-type organic fertilizer granulator is used to granulate most biodegradable organic materials into commercial-quality fertilizer granules for sale, of course, after fully composting. It breaks through the conventional organic granulation process. Before granulation, the raw materials do not need to be dried and crushed. Direct granules can be processed into spherical particles and can save a lot of energy. The granulator can be customized according to customer needs.

Working Principle of Newly Developed Organic Fertilizer Granulator

The new granulation machine, using the high-speed rotary mechanical stirring force and the resulting aerodynamic force, makes fine powder in continuous mixing, granulation, spheroidization, and dense process in the machine, so as to achieve the purpose of granulation. The particle shape is spherical. The spherical degree is ≥ 0.7. Particle size is generally between 0.3-3 mm. The granulation rate is ≥ 90%. The size of the particle diameter can be adjusted by the amount of mixing material and spindle speed. Under normal conditions, the lower the amount of mixing materials added and the higher speed, the smaller the particles are, and vice versa. The finer the basic particles of the fine powder material, the higher the sphericality of the particles, and the better the ball quality. The qualification rate of the machine is as high as 80-90%, which is suitable for many different formulations. The ball rate is less than 15%, and the uniformity of particle size can be adopted according to the user’s requirement.

Granulated Organic Fertilizer Making Machine Application

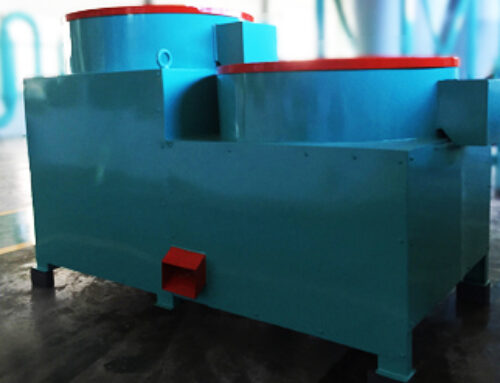

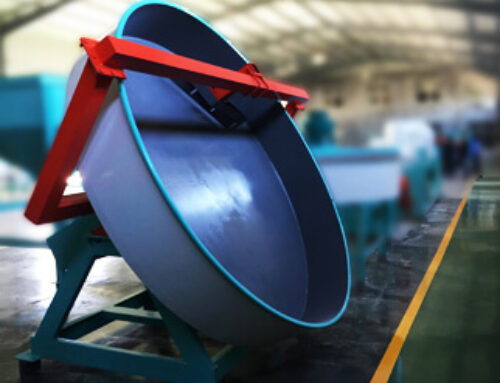

This organic fertilizer granulator has a specialty for organic fermentation fertilizer granulation of livestock manure, pile retting fertilizer, green manure, cake fertilizer, peat, soil miscellaneous fertilizer, microbial, and other municipal solid waste. It can adapt to a variety of different formulations. Organic fertilizer compressive strength is higher than disc fertilizer granulators and rotary drum fertilizer granulators. The Wet type organic fertilizer granulator is suitable for organic fertilizer direct granulation after fermentation, saving the drying process and greatly reducing manufacturing costs.

Wet Type Organic Fertilizer Granulation Machine Features

1. The granulation particles are in a ball shape.

2. Organic content can be as high as 100%, to achieve pure organic granulation.

3. In a certain force, organic particles can be mosaic with each other to grow into organic particles without adding binder.

4. Organic fertilizer granules are solid particles. The granules can be sieved to reduce drying energy consumption.

5. After fermentation, organic matter does not need to dry. Raw materials containing water can be 20-40%.

The organic fertilizer-making machine achieves a material granulation process in a reasonable and thorough manner. The whole organic fertilizer production process is smooth, simple, and environment-friendly, saves production costs, improves work efficiency, and reduces working hours.

Technical Data of New Type Organic Fertilizer Granulation Machine

| Name | Model | Dimension(CM) | Capacity (t/h) | Power (Kw) |

| L*W*H | ||||

| Wet-type Organic Fertilizer Granulator | JCZL-60 | 355x143x98 | 2-3 | 37 |

| JCZL-80 | 416x166x117 | 3-5 | 55 | |

| JCZL-100 | 530x210x138 | 6-8 | 75 |