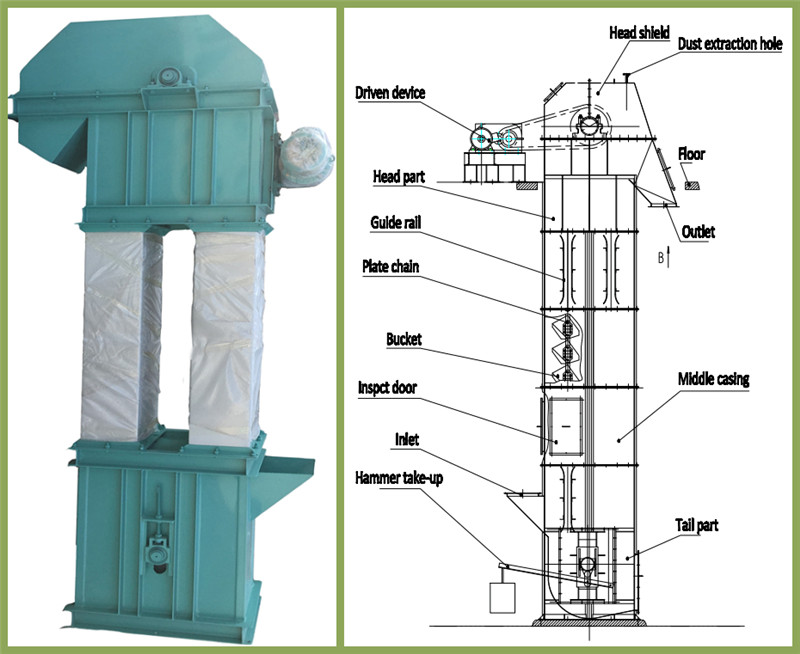

Bucket Elevator Belt Introduction

A bucket elevator or bucket conveyor is used for lifting or conveying materials from a low point to a high point. The materials are sent into the hopper through a vibration table, and then the machine automatically transports up and runs continuously. Transfer rate can be adjusted according to conveying capacity and choose to lift height on demand. The hopper is designed and manufactured in our own factory. A non-toxic hopper enables the bucket elevator widely used application. All sizes are designed in accordance with the actual needs of supporting vertical packaging machine and metering machine, which is suitable for food, medicine, chemical industrial products, screws, and nuts. Use signal identification to control the automatic start and stop of the machine. Bucket elevators can be divided into chain, plate, and belt types.

Bucket Elevator Working Principle

The material is sent by hopper from the bottom of the storage and lifted to the top with a conveyor belt or chain. And then it turns over the top wheel and then flips down. The bucket elevator draws the material into the receiving bin. The belt of the bucket elevator is generally made of a rubber belt, mounted on the lower or upper drive roller and turnabout drum. Chain-driven bucket elevator is generally equipped with two parallel drive chains. It is a pair of drive sprockets on the top or bottom, and the next or above is a pair of changes to the sprocket. The bucket elevator is also equipped with a chassis to prevent dust.

Advantages of Bucket Materials Handling Conveyor

- Simple structure, small horizontal size, and little floor area

- Great lifting height, good transport capacity, full closed body, and small environmental pollution

- Whirlston bucket material handling conveyors are with rugged construction. They are designed to withstand many years of heavy-duty operations, being widely used in organic fertilizer production plants.

Bucket Elevator Operation Points for Attention

- The operation must comply with the principle of no load start and no load parking. The worker should open the machine first. Add materials after the machine normally running. The machine should be empty before stopping operation.

- The feed should be even and the outlet should be smooth so as not to cause clogging. If the material clogs the machine, the worker should immediately stop feeding, close down the machine, pull the chassis board and remove the blockage. Note that the worker can not directly insert hands into the base.

- The hopper belt should be in the middle of the barrel in normal work. If the worker finds a phenomenon of deviation or the bucket belt is too loose causing the collision between the hopper and the barrel friction, it should be timely adjusted through the tension device.

- The worker should prevent large pieces of materials into the base for fear of breaking the hopper or influencing the machine to work properly.

- Similar to an inclined belt conveyor, the worker should regularly check hopper belt tension. If it is loosening, shedding, hopper skew, or damaged, it should be timely repaired or replaced in order to avoid more serious consequences.

- The worker should clean accumulated materials in the base and then start up the machine in the event of a sudden stop working.