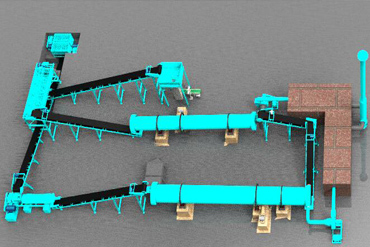

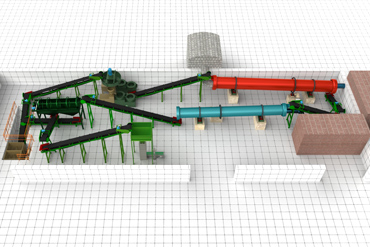

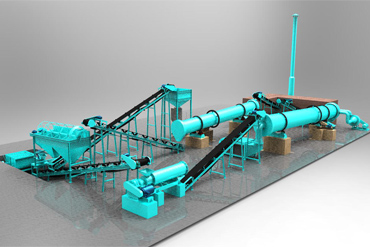

Customized Compost Fertilizer and Granular Organic Fertilizer Manufacturing Plant

This organic fertilizer manufacturing plant can produce both powder compost fertilizer and granular organic fertilizer which satisfy different customers' demands for finished products. The whole line is equipped with high-efficiency fertilizer-making machines to promise continuous production. Powder organic fertilizer production process: composting-crushing-sieving-packaging. Granular organic fertilizer: mixing-granulation-drying-cooling-screening-packaging. The organic fertilizer production line will be customized according to your requirement and your local conditions. We will offer you a complete organic fertilizer production solution.