Nowadays, starting an organic fertilizer production line under the guidance of the right business plan can improve the supply of non-harmful fertilizer to farmers, and it has been found that the benefits of using organic fertilizer far outweigh the cost of organic fertilizer plant setup, not only referring to economic benefits but also including environmental and social efficiency. Switching organic wastes to organic fertilizer can help farmers to extend soil life, improve water quality, boost crop production, and eventually increase their yields. Then it is of the essence for investors and fertilizer manufacturers to learn how to make waste into fertilizer and how to start an organic fertilizer business. Here, we will discuss the points that need attention from the following aspects when starting an organic fertilizer plant.

To Business Owners: Why Start Organic Fertilizer Manufacturing Process?

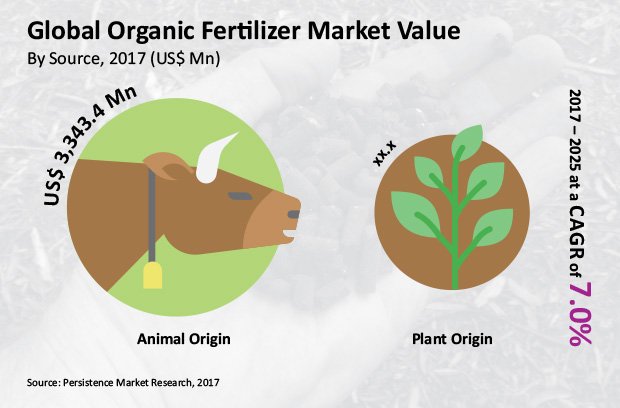

◆ Organic fertilizer business being profitable

Global trends in the fertilizer industry point to environmentally safe and organic fertilizers that maximize

◆ Government support

In recent years, governments have provided a series of initiatives to support organic farming and organic fertilizer business, including targeted subsidies, market investments, capacity expansion, and financial assistance, all of which can promote the wide use of organic fertilizers. For instance, the Indian government offers the promotion of organic fertilizer up to Rs.500/- per hectare. And in the EU, the government is promoting the organic sector via conversion subsidies and large subsidies on agricultural inputs. Besides, Nigeria is committed to taking the necessary steps for promoting the use of organic fertilizer in order to develop the Nigerian agriculture ecosystem for creating sustainable jobs and wealth.

◆ Awareness of organic food

People are becoming more aware of the safety and quality of the food they eat. The demand for organic food has grown robustly for the past few years. From a US$ 15 billion market in 1999, the global organic food and drink market has grown to become a US$ 80 billion market in 2014. It is fundamental to protect food safety by using organic fertilizer to control the production source and avoid pollutants entering the soil.

◆ Plentiful raw materials of organic fertilizer

There are large volumes of organic waste are generated daily all over the world. Statistically, there are 2.12 billion tons of waste globally each year, most of which can be recycled into things of value. If interest in converting wastes into fertilizer, click How to use organic fertilizer granulator for recycling organic wastes.

Raw materials for producing organic fertilizer are plentiful and extensive, such as agricultural wastes (like straw, soybean meal, cottonseed meal, and mushroom residues), livestock and poultry manure (like cow dung, pig manure, sheep muck, horse dung, and chicken manure), industrial waste (like vinasse, vinegar residue, cassava residue, and sugarcane ash), household garbage (like food waste or kitchen garbage) and so on. It is the plentiful raw materials that make the organic fertilizer business popular, prosperous, and successful in the world.

More Resources:

◆ cow dung organic fertilizer-making technology

◆ effective food waste management method – making it into organic fertilizer

When designing an organic fertilizer plant, investors should consider the business scale according to budget, production capability (ability to maintain the level/scale of organic fertilizer production), and supply of raw materials (output should be equal to a daily supply of organic materials, to keep continuous production).

Proposed Site of Organic Fertilizer Plant

The choice of site location for an organic fertilizer plant should follow the below principles:

- It should be situated in close proximity to the supply of raw materials for organic fertilizer

production, aiming at reducing transport costs and transportation pollution. - The site should be close to places with adequate water and power supply.

- Factories should be located in areas with convenient transportation so as to reduce logistical challenges and transport costs.

- The proportion of plants should satisfy the requirement of the production technology process and reasonable layout, and leave appropriate room for further development.

- Keep away from a residential area to avoid affecting the lives of residents because there is more or less a special odor generated during the process of organic fertilizer production or raw materials transportation.

In a word, the source materials required to establish the industry, especially poultry manure and plant waste, should be readily available from the marketplace and poultry farms in close proximity to the proposed plant site.

How to Choose Machines for Organic Fertilizer Plant

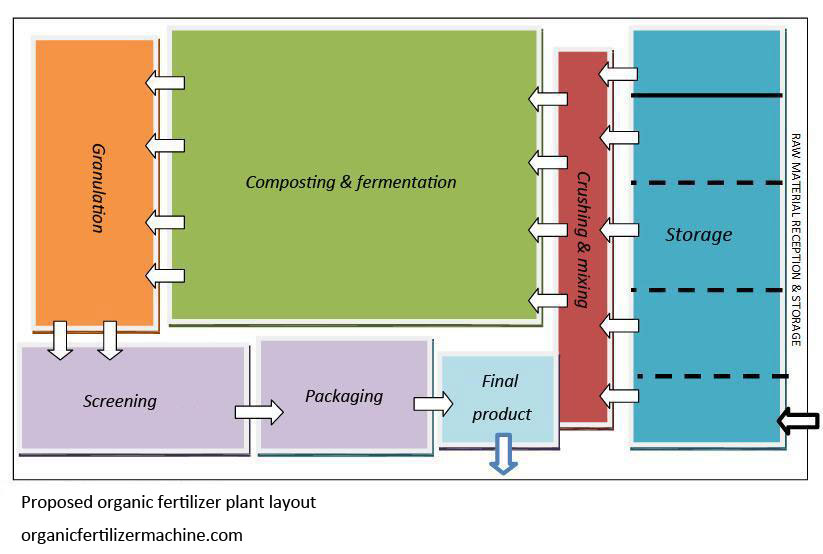

Organic fertilizer plant mainly contains two types – the pretreatment of raw materials(including composting, crushing, and mixing) and the granulation process(including granulating, drying, cooling, screening, and packaging). For the starters who have limited capital investment in organic fertilizer plants, we propose plants with small-scale production as their best choice. Taking an 800kg/h organic fertilizer production plant with a quite low initial investment for instance, Whirlston proposes suitable organic fertilizer-making machines for investors and fertilizer manufacturers: small groove-type compost turner, semi-wet crusher, horizontal blender, disc pan granulator, fertilizer screening machine, and automated packaging machine.

As the first but significant step of organic fertilizer manufacturing, composting quality has a great influence on the quality of fertilizer, so it is very essential for investors to focus on the following factors that can

determine the quality of compost and fermentation:

- C:N ratio: the appropriate C:N ratio is from 25:1 to 30:1. Remember that this ratio can be adjusted by

mixing together organic raw materials with suitable contents.

- Moisture: The best water content is always around 50%-60% when composting organic raw materials.

- Sufficient oxygen: compost piles should be turned often to allow all parts of the pile to absorb oxygen, and the ideal oxygen concentration is 18%.

- PH value: the optimum PH level of compost is between 5.5 and 8.

There are mainly three different shapes of organic fertilizers (as pic shows) in the current market, so investors can choose to produce the popular shape organic fertilizer according to local market demand. In order to make it easy to choose, Whirlston offers three generalized and accepted approaches and machines for the granulation of organic waste, including a wet-type organic fertilizer granulator, flat die pellet mill, and double roller extrusion granulators.

mixing together organic raw materials with suitable contents.

mixing together organic raw materials with suitable contents.