Inclined Belt Conveyor is a kind of economic and logistics conveying system which is composed of rhythmic flow lines. It is a kind of fertilizer conveyor system that has the function of expansion, and the distance and height can be adjusted in a certain range. This machine completes the transfer work through the same conveyor belt, the change in the conveying distance is realized by the relative movement of the fixed frame and telescopic frame. When the telescopic frame is extended or retracted, the transmission length of the conveyor can be changed. The machine has the advantages of a compact structure and flexible control, and the conveying surface is smooth, the positive and negative operation can be changed at any time.

Mobile belt conveyor is mainly used in organic fertilizer plants, feed plants, grain storage, building site, mine and quarries, factories, station, wharf, and other frequently exchanged places for loading and unloading. It is an ideal conveyor system for short transport and handling of bulk materials or components, the equipment adopts a steel tube structure, is lightweight, and with good mobility. The rotating device is an electric drum and is provided with two wheels of pneumatic tires and steel wheels.

Advantages of Organic Fertilizer Conveyor Belt

- High precision, hard surface gear, and high bearing capacity.

- Long life, structure gathers, covers a small area, lightweight.

- High efficiency, easy to use, and good mobility.

- Simple structure, and easy maintenance, the bottom is equipped with a universal wheel and flexible mobile.

- Stable operation and little noise.

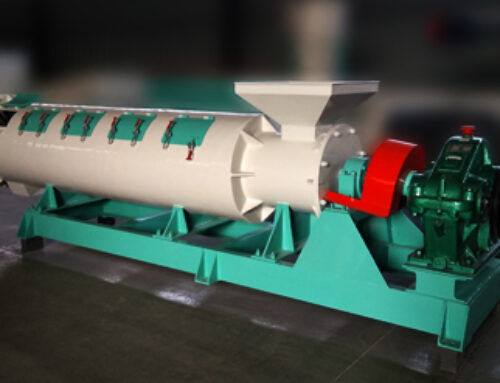

Working Principle of Whirlston Inclined Belt Conveyor

An inclined Belt conveyor is mainly composed of two ends of the roller and a tight cover on the conveyor belt, drive the conveyor belt to rotate the drum known as the driving drum (driving roller), and another is to change the direction of movement of the conveyor drum known as the turnabout drum. The driving drum is driven by a motor through a speed reducer, and the conveyor belt is driven by friction between the driving roller and the conveyor belt. The drive roller is usually installed on the discharge side, in order to increase traction, it is conducive to drag, the material is fed from the feeding end, falling on the rotating conveyor belt and conveying the material to the discharge end.

There are four main requirements for equipment maintenance:

Like bucket elevator conveyors, the contents of the maintenance of the conveyor equipment include routine maintenance, regular maintenance, regular inspection and accuracy inspection, equipment lubrication, and cooling system maintenance is an important part of equipment maintenance.

- Cleaning: inside and outside of the equipment are clean and tidy, the sliding surface, lead screw, rack, gearbox, oil hole, and other places are without oil pollution, to clean the cuttings, debris, and dirt around the equipment.

- Tidy: tools, accessories, parts (products) to be placed neatly, pipes, and lines to be organized.

- Good lubrication: no friction phenomenon, normal oil pressure, oil mark is bright, change oil on time, oil way is smooth. Oil quality meets the mechanical requirements.

- Safety: comply with safety operation procedures, do not use equipment overload, and timely eliminate of unsafe factors.