We provide Eco drying solutions with exhaust air control to meet your needs to have clean exhaust and smell-free.

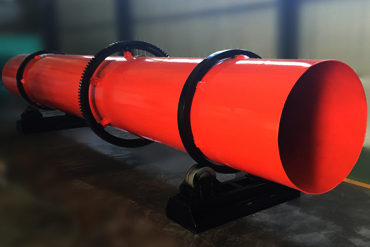

Working Principle of Rotary Drum Organic Fertilizer Drying Machine:

The rotary drum dryer runs on the principle that the belt and belt pulley, driven by the main motor, transmit to the driving shaft through reduction gears, and then split gears installed on the driving shaft can engage with a big gear ring fixed on the engine body, working in the opposite direction. Materials are added from the feed end, then enter into the drum under the attractive force of hot-blast air generated by the hot-blast heater and draught fan. During this process, the lifting board installed in the drum would turn over materials continually so as for even drying, and materials would outflow from the discharge hole after drying. after being dried by the rotary dryer, the temperature of fertilizer granules/prills can reach 60-80℃. Then the hot organic fertilizers are transported to the rotary cooler for further processing.

Advantages of Rotary Drum Fertilizer Dryer:

- With low investment and good economic returns, our rotary dryer has stable running performance, high reliability, and strong anti-overloading capacity.

- Without the discharge of three wastes, this machine is stable to operate and convenient to maintain. Moreover, it has advanced technology, large handling capacity, limited fuel consumption, and low drying cost.

- The lifting board of a rotary dryer has a reasonable layout and angle design, reliable performance and appearance so as for a high heat utilization ratio, even drying, and obvious energy-saving effect.

- With superior quality anti-corrosion and wear-resistant materials, this rotary dryer has an impact structure, a longer lifespan, and higher running efficiency.

- Rotary drum dryers are equipment for the treatment of numerous products, such as chemical products, fertilizers, minerals, solid waste materials, vegetables and fruits, and a large range of granulated fertilizers or pulverized solid products. They are suitable for drying a wide range of materials because of their ability to process materials having considerable variation in size and composition.

Technical Data of Rotary Dryer Machine

| Name | Model | Dimension(CM) | Capacity (t/h) | Power (Kw) |

| L*W*H | ||||

| Rotary Dryer | HGJ-1.0 | 1080x221x170 | 1-2 | 7.5 |

| HGJ-1.2 | 1300x236x180 | 2-3 | 7.5 | |

| HGJ-1.5 | 1630x280x226 | 3-5 | 11 | |

| HGJ-1.8 | 1950x330x245 | 6-10 | 22 | |

| HGJ-2.0 | 2150x417x260 | 8-14 | 37 |