A chain mill crusher is better suited to breaking up manure compost, sludge compost (after composting), and substandard organic fertilizer granules (after the screening process) into smaller particles.

Introduction of Chain Mill Crusher

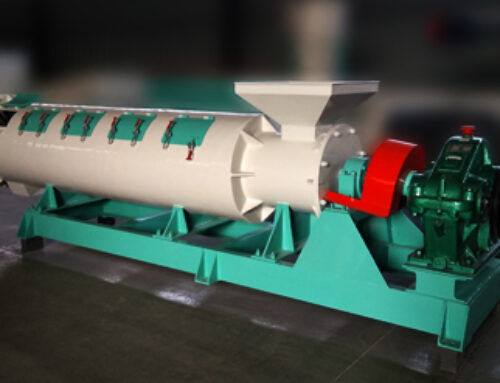

Chain mill crusher is also called a “Vertical Chain Crusher”. It is a middle-size organic fertilizer pulverizer that is made up of a sturdy body, inside of which moves a rotary main axle (rotation shaft) and chains(fig 1).

Crushers are available with capacities of 1-2 tons per hour up to 5-8 tons per hour. The capacity of chain mill organic fertilizer crusher (same model) is primarily determined by reduction ratio 1, and secondarily by materials hardness. As we have described above, a chain crusher is mainly used in the fertilizer production process, which is to say, it can crush materials of soft hardness such as agricultural waste, peat moss, biogas waste, etc. A large model should be used if you want to achieve maximum productivity and a high reduction ratio.

- The Reduction Ratio is broadly defined as the ratio of the feed size to the product size in any crushing operation. It is an element in determining the crusher capacity and is an indicator of crusher efficiency.

Chain Organic Fertilizer Crusher Highlights

◆chain crusher comprises a semi-closed shell used as a crushing cavity and a feeding hopper connected with one upper side of the shell.

◆motor, the output shaft which extends into the shell, is connected to the center of the upper-end surface of the shell with the aid of bolts. The ratio of the motor gear to that of the axle and the power of the motor will determine the rotational speed.

◆this compost fertilizer crusher has two crushing layers. The materials are crushed through the crushing layers formed by a plurality of crushing chains which are evenly distributed on the circumference of the chain wheel with the aid of the bolts.

◆chains are hard and have high wear resistance, which promises organic fertilizer-crushing efficiency. Reducing or increasing the quantity of the chains will achieve coarse or fine grinding.

◆the chain crusher has the advantages of simple structure, economy, practicability, and good crushing effect.

Working Principle of Chain Mill Compost Fertilizer Crushing Machine

Chain crushers differ from the other crushers in that they do not work by squeezing a captured lump-instead a plurality of relatively high-speed crushing chains strikes the organic materials in mid-air and crush them into smaller particles. Breakage occurs when the rotary wheel drives the crushing chains rotating at a super high speed with the aid of a motor. The effect can be extended by adding a second hammer wheel, which is the reason why chain mill crushers are designed with a 2-layers structure.

Technical Data of Chain Crusher

|

Name |

Model |

Dimension(CM) |

Production Capacity (ton/hour) | Power (kW) |

|

L*W*H |

||||

|

Chain Mill Crusher |

LSFS-60 |

100X73X170 | 1-5 |

15 |

| LSFS-80 | 125X100X210 | 2-8 |

22 |