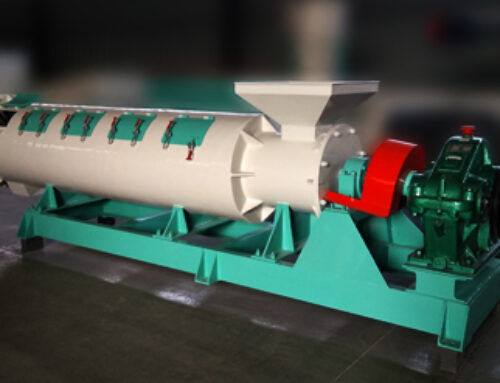

Introduction of Self-propelled Compost Turner

With the design of 4 wheels run, our self-propelled compost turner can be driven and handled by one person for free moving forward, reversing, and turning, which is often used before an organic fertilizer crusher. As is well known, the advanced fermentation technology refers to microorganism aerobic fermentation, and our self-moving compost turner is designed according to the principle of aerobic fermentation, providing enough space for homogeneous bacteria to play its role. Therefore, this machine is more suitable for the technological requirement of microbial fermentation materials, and it can effectively mix sticky materials, microbial preparation, and straw powder evenly. In addition, this compost turner can be used to compost various organic raw materials, working well not only in a wide outdoor open area but also in a workshop and greenhouse.

Working Principle of Self-propelled Compost Turner

Adopting four wheels design, the whole machine rides on the base of elongated shape fertilizer banked up in advance, and its rotary cutter shaft (hung under the rack implements) implements the turning and mixing, bulking, moving, and stacking, then shaping new bar-type stacks after compost turner machine passing. Meanwhile, the design of the machine conforms to the function mechanism of aerobic fermentation, creating a better aerobic environment for materials fermenting.

Feature of Self-propelled Compost Turner

- With proper overall structure and advanced technology, our pile-turning machine has reliable performance with large turning capacity, high productivity, and strong adaptability to the site, easy to control and convenient to maintain.

- The machine can turn over 400-500 cubic compost per hour, converted into 160-200 ton finished fertilizer, all of which only takes about fifteen minutes and needs low energy consumption, making finished fertilizer with obvious price predominance.

- Using this machine can make loose materials warm in 24h – 48h, deodorize them within three days, become fertilizer in 7-10 days, faster than the speed of deep groove fermentation, and effectively prevent the generation of noxious gas and foul gas.

- Furthermore, this pile-turning machine also has a crushing function, greatly saving the cost of time and labor and significantly improving the production efficiency and product quality of organic fertilizer plants.

Operating Requirements of Self-propelled Compost Turner

- The place for turning piles should be flat and firm, and there should be no concave-convex area higher than 50mm in the operation zone.

- Bar-shape pile turning: width should be within 2000mm and height should be less than 800mm, stacking in a straight line and bar shape.

- There should be enough space at both ends of material piles for the machine to turn around, and the interval between material piles should be over one meter.

- This machine is a self-propelled compost turner, only used to compost material piles for organic fertilizer, which cannot be used as a vehicle for walking and loading.

Technical Data of Self-propelled Compost Windrow Turner

| Model | XGFD-2000 |

| Width of the pile | 2000mm |

| Height of the pile | 600mm-800mm |

| Plies distance | 0.5-0.8m |

| Maximum Diameter of Materials | 250mm |

| Power | 36hp

Water-cooled, Electric start |

| Maximum Rotational Speed | 2200 revs per min. |

| Rated Horsepower Speed | 2200 revs per min. |

| Working Speed | 7.5—8 m/min. |

| Traveling Speed | 50m/min.

Three forward gears, A reverse |

| Dia. Of Blades | 600mm |

| Production capacity | 400—500m³ per hour |