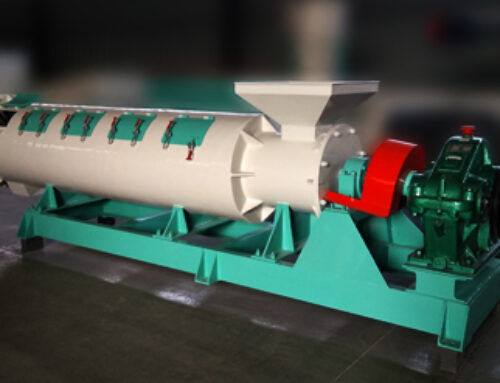

The automatic quantitative packaging machine is a new generation of intelligent bagging equipment. The fertilizer packager is mainly composed of four parts: an automatic weighing device, conveying device, a sewing device, and computer control. This model has the advantages of reasonable structure, beautiful appearance, stable operation, energy saving, electricity-saving, convenient operation, and accurate weighing. Specially designed feeding and bucket metering, whatever bagging or unloading, it does not affect the measurement. Automatic quantitative packaging machine, fast packaging speed, high packaging accuracy, is able to save 1/3 of the operating time. The main engine adopts a three-speed (fast, medium, and slow) feeding and special feed stirring structure, advanced digital frequency conversion technology, sampling and processing technology, anti-jamming technology, and automatic compensation and correction of errors. It is suitable for quantitative packaging of powder and granular materials.

Wide Application of Automatic Organic Fertilizer Packaging Machine

Automatic packager widely used in:

- Fertilizer: organic fertilizer, compound fertilizer, ammonium phosphate, urea granules, porous nitramine fertilizer, heavy calcium fertilizer, BB fertilizer, potash fertilizer, and other various mixed fertilizers.

- Chemical Engineering: PVC, PE, PP, ABS, polyethylene, polypropylene, sodium chlorite, etc.

- Grain: corn, sorghum, soybean, rice, buckwheat, rice, millet, wheat, etc.

- It can also be used in powdered things like flour and starch.

Features of Automatic Packager

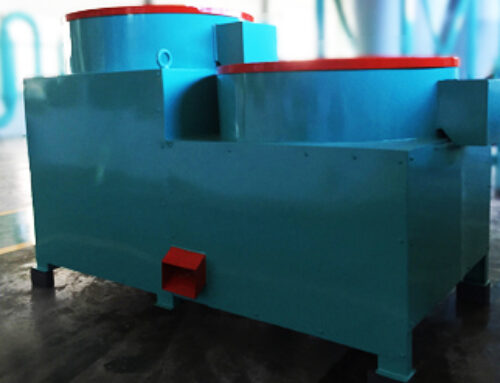

This machine is the last part of the organic fertilizer production plant. According to the viscosity and not easy mobility of fertilizer, screw feed, and material contact parts are made of 304 stainless steel, which improves the feeding speed and corrosion resistance. The electrical system is equipped with domestic and international advanced brand electrical appliances, to ensure the reliability of the machine in a long working time. Specific features are as follows:

- Suitable for woven bags, gunny bags, cloth bags, plastic bags, etc.

- Use high stability, high precision weighing sensor, and weighing module, have simple interface operation and intuitive display.

- Self-adopting software, automatic setting of control parameters, and automatic correction of drop.

- Independent packaging weight input and display window, which uses high brightness LED display. Menu operation is simple, intuitive, and friendly.

- An Independent weighing system has high weighing precision and fast speed.

- The quantitative range is wide with high precision, matching table can go up had down for conveying bags.

Working Principle of Organic Fertilizer Bagging Equipment

The use procedure of packaging machine: manual assistance putting the bag, material-feeding weighing, bag nipping, unloading, and packaging automatically.

When the packing machine is in the automatic operation state, the weighing control system opens the door to start feeding, the feeding device has fast and slow speed feeding models. When the weight of the material reaches the set value of the feed material, stop fast feeding and keep the feed slowly. When the weight of the material reaches the final set value, the feeding door is closed and the dynamic weighing process is completed. The system detects whether the bag clamping device is in a predetermined state, when the bag is clamped, the system sends out the control signal to open the weigh hopper discharge gate, after the material is put out, the unloading door of the weighing hopper is automatically closed, loosen the bag clamping device after unloading the material, then the bag is sewn and transported to the next station.

Technical specification:

| Model | Power | Voltage | Air source consumption |

Air source pressure | Packing specification | Packing pace | Packing precision | Weighing way |

| DGS-50F | 1.5kw | 380v | 1 m³/h | 0.4-0.6 M pa | 5-50kg | 3-8bag(s)/minute | ±0.2-0.5% | Sensor |